Life Sciences

A new generation of CDMO services 15th March 2024

In CDMO services, Indena acts as a strategic partner, not just as a supplier, with full commitment to developing new HPAPIs and APIs.

Custom Development and Manufacturing services have been one of Indena’s key areas of expertise for more than 30 years now. Leveraging on its analytical, development and manufacturing capabilities, Indena positions its services in a high added value segment, producing complex molecules requiring both leading technologies and significant expertise in R&D and industrialisation, encompassing high containment handling and production of HPAPIs from early stage to commercialisation.

Indena’s goal is to offer its customers the possibility of carrying out synthetic processes in a wide range of conditions, both for naturally derived molecules (from botanical sources or from microbial fermentation) requiring semi-synthetic steps and for total-synthetic molecules. As a highly reliable Western European API producer, Indena displays a key uniqueness on Highly Potent APIs down to 20ng/m3 OEL, irrespective of their source, for which Indena is highly skilled and well-equipped.

This expertise includes payloads for ADCs, with a backward integration on fermentation for toxins requiring this step and freeze-drying ability in high containment.

This expertise includes payloads for ADCs, with a backward integration on fermentation for toxins requiring this step and freeze-drying ability in high containment.

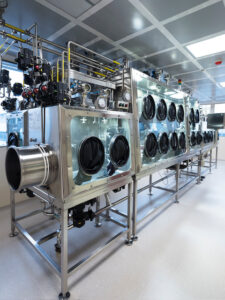

Indena has been continually investing in know-how, personnel and equipment for its CDMO services for many years. Its most recent expansion program includes the construction of a brand new 400 sq m R&D laboratory equipped with 12 fume hoods, two walk-in fume hoods, a laminar flow fumehood, and two gloveboxes able to host 15 R&D scientists.

This laboratory has been conceived and built specifically to handle Highly Potent APIs and will be up and running by mid-2024.

Formula for clients’ success

In CDMO services, Indena acts as a strategic partner, going beyond the mere client/supplier relationship, with full commitment to developing new HPAPIs and APIs, from early clinical stages to commercial-scale manufacturing.

In order to always meet its clients’ expectations, every year Indena invests in innovative technologies and services. The quality and efficiency of its equipment and facilities, however, are only half the story.

At Indena, it’s well understood that highly qualified, motivated and trained technical staff, supported by a corporate culture that is strongly oriented toward quality and rigorous HSE policies, is essential to ensure that operations run safely, seamlessly and efficiently.

Indena is also well-supported by a strong regulatory department that continuously interacts globally with the most important national health authorities, such as FDA, EMA, AIFA, ANSN and PDMA.

The strengths of Indena’s CDMO offer are then supported by manufacturing excellence programs, the highest equipment standards and qualified human resources.

Pioneering project

Indena’s CDMO experience dates back many years and the first project the company managed in this field was related to the first oncological blockbuster drug, paclitaxel. The challenge included the development of a sustainable supply chain for the ingredient, the development of a method of insulation under high-containment conditions and the analytical methodology of control according to stringent pharmaceutical protocols in terms of purity and stability.

Indena’s CDMO experience dates back many years and the first project the company managed in this field was related to the first oncological blockbuster drug, paclitaxel. The challenge included the development of a sustainable supply chain for the ingredient, the development of a method of insulation under high-containment conditions and the analytical methodology of control according to stringent pharmaceutical protocols in terms of purity and stability.

During the development phase, the drug was extracted from the bark of the Pacific Yew Tree in a way that was not sustainable. To make the drug available on a commercial scale, the first challenge Indena had to face was to build a robust supply chain for the biomass and this meant developing its own Yew Tree cultivations. The second challenge was related to the development of a strong industrial method to extract and purify the intermediate 10-deacetylbaccatin III.

The third problem was the development of a robust and clean analytical frame for the project, complying with the most stringent regulations for pharmaceutical products. Moreover, Indena had also to develop its own synthetic methods to convert the intermediate 10-deacetylbaccatin III into the final API.

The solution devised by Indena for paclitaxel was an extraordinary result as there were no alternatives for a real and sustainable production of the ingredient with the traditional method from the bark of the Pacific Yew Tree. The solution found by Indena was the only one possible and it has created a totally unique expertise: what Indena has learned in this experience of working with Nature has taught the company to manage complex molecules of any type, from both analytical and production perspectives.

The success of its paclitaxel experience allowed the company to deeply change and enlarge its capacities and to face the market’s needs through a specific approach, which makes Indena a reliable partner for pharma and biotech companies’ success.

Current scenario

The increasing number of oncology NCEs and antibody-drug conjugates, coupled with a growing focus on personalised medicine, is shaping the demand for CDMO services. The HPAPI market is undergoing a shift toward NCEs characterised by higher potency, growing molecular diversity and segmentation for specific populations.

As shown by its long story and expertise, and unlike newcomers in the field, Indena can count on extensive know-how in safely handling HPAPIs, complemented by state-of-the-art equipment and installations.

Within its long-term strategy, Indena has kept ahead of the curve by timely investment in specialised containment facilities that guarantee that both employees and the external environment are safe from exposure, capitalising on more than 30 years of know-how in high containment.

Nowadays, Indena manufactures 12 commercial HPAPIs: fully synthetic, semi-synthetic and fermentation molecules. This is now one of the company’s core areas of expertise. Each substance within Indena is assigned an Occupational Exposure Level and allocated to the proper production line according to the required handling and containment rules. At the facility in Settala, Italy, Indena can handle HPAPIs with an OEL from 1 mcg/m3 to 20 ng/m3 (with ongoing SMEPAC tests to reach 1 ng/m3).

Moreover, Indena has a fermentation department for carrying out living cells-based bio-transformation or secondary metabolite production, which can be exploited for the in-house production of toxins used in ADCs payload, guaranteeing an integrated and independent supply chain. Indena masters GMP microbial fermentation and bio-transformation, and thanks to the availability of high containment lines for the downstream phase, it is an ideal partner for fermentation HPAPI development.

Sustainability

Climate change is one of the most urgent sustainability challenges that people, governments and companies have to face, and this involves a responsible use of energy. Indena has always been oriented and committed to reducing fossil fuel consumption and use, saving energy and achieving high levels of energy self-production. This commitment is mainly achieved thanks to the company’s plant management, starting with its most important plant, located at Settala near Milan, where Indena’s CDMO activities are conducted.

Among the actions taken for smart use of energy at the Settala site, there is a natural gas cogenerator plant, operational since 2016. It produces 16,566,000 kilowatt-hours per year, both electric and thermal energy, and enables a reduction of 1.699 Tons Equivalent Petrol (PET), which means a reduction of 2,500 tons of CO2 emissions per year.

Another important action for sustainability is the use of renewable energy, and Indena is equipping all its European sites with state-of-the-art photovoltaic panels.

Indena’s factories in Europe are all ISO 14001 Environmental Management System and ISO 45001 Occupational health and safety management system certified.

All the actions taken in favour of sustainability also enable Indena to be fully reliable in terms of business continuity and therefore to be a reliable partner for its many clients.